HIPERFLOOR® by Husqvarna is a complete concrete surface polishing system, which enhances the beauty, strength and abrasion resistance of concrete floors while reducing maintenance and costs.

HIPERFLOOR® can radically transform a broad range of new and old concrete floors. By mechanically refining the already hard concrete surface through grinding, polishing and chemical treatments, we can bring virtually any surface to a whole new level of beauty, functionality and strength. With different specified processes, a flooring solution can be tailored to fit any requirement – aesthetics, floor flatness, gloss and price.

HIPERFLOOR® is available in three distinctive surface finishes: Premium, Commercial and Industrial. Each finish has a well-defined specification for the working process and selection of grinding/polishing tools and chemicals.

HIPERFLOOR® Premium Finish

A decorative, high-gloss finish for exposed aggregate floors. Premium Finish is an indoor application for showrooms, high-end real estate and areas where aesthetic properties including flatness and reflectivity of the floor are top priority. The result is a surface that shines and offers exceptional durability.

– Reflective and decorative finish

– Floor flatness

– Extremely high quality and durability

– Hygienic and easy to clean

– Exceptionally resistant to abrasion

HIPERFLOOR® Commercial Finish

A medium-gloss finish for semi-exposed and low-exposed aggregate floors. Commercial Finish is an indoor application aimed at retail areas, shop fronts and indoor public spaces. The result is a floor that offers functionality and low maintenance but is still aesthetically pleasing.

– Easy to clean and maintain

– Resistant to wear and spills

– Abrasion-resistant

– Slip-resistant

– Minimal lifetime cost

HIPERFLOOR® Industrial Finish

A low-gloss finish customised for industrial floors. This process is primarily an indoor application targeting large areas such as warehouses and department stores where flooring functionality is of primary concern. The result is a hardwearing floor that offers a safer and cleaner environment.

– Minimal lifetime cost

– Withstands the toughest use

– Slip-resistant

– Resistant to spills, abrasion, oils and dusting

– Easy to clean

Environmentally sensible

HIPERFLOOR® is the smart choice to reduce environmental impact. The process transforms existing concrete substrate into a wear resistant floor. The process incorporates the use of products that cause very little environmental stress or waste.

Light reflective

In addition to reduced maintenance costs is also the added benefit of reduced lighting energy requirements. This reduction in cost is due to the higher light reflectivity of the surface.

Hard and resistant

With the HIPERFLOOR® method, we take an already hard material and increase the surface density and abrasion resistance to a level where the concrete surface is extremely resistant to wear and marking.

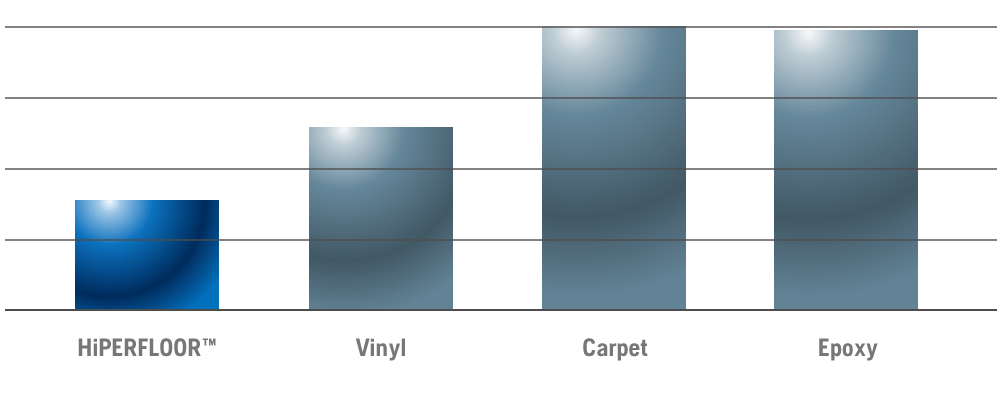

Selecting the HIPERFLOOR® concrete polishing system significantly increases durability and reduces life cycle maintenance costs. The absence of a surface coating reduces costs traditionally associated with flooring installations. The result is a smoother surface with reduced cleaning costs.

Chemicals used in the process

The HIPERFLOOR® process contains three different chemicals. First is the pore filler GM 3000™ which is used to fill out pores and imperfections in the surface.

Then is the densifier (HIPERHARD™ or HIPERLITH™) to strengthen the concrete making it more abrasion- and scratch resistant, while adding also some stain resistance, limiting efflorescence and dustproofing your surface.

This treatment also makes the surface more responsive to the diamond tooling and hence easier to polish. Last is the sealer (HIPERGUARD™) which will help protect your polished floor from stains and penetration of fluids but still keeping the surface diffusion open.